DRYER

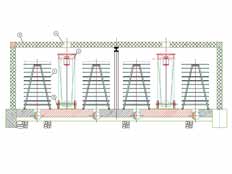

The static or chamber dryer is composed of one or more chambers where the bricks to be dried are introduced, placed on supports on wheels or shelves.

When the chamber or cell is full of bricks it closes and the drying process started. In the static dryer the product remains still and the internal thermo hygrometric conditions are changed.

In accordance with the chemical-physical characteristics of the brick to be dried, the drying cycle will have a different drying recipe adjusting the temperatures and the cycle times.

The possibility to adjust the firing curve per each cell, is an important feature for small productions where the variety of the range produced allows adapting the more appropriate drying process to each

chemical-physical feature.

The use in sequence of the chambers, allows to recover at the end of the drying cycle part of the residual heat that is channeled in the chamber that has just been filled.

The devices for the production of heat are installed in a thermal room this through suitable piping and dampers load the hot air into the working chamber.

The supervision system controls through the PLC all the operations and is essential to optimize the drying cycle, consumption and minimize waste.

Part of the heat can be recovered from the kiln cooling zone, which suitably mixed with cold air, allows drying thus optimizing energy costs.

EVOLUTION RAPID DRYER

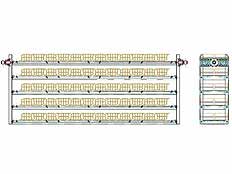

This type of dryer is composed of two overlapped tunnels, interconnecting on the heads, on which the bricks placed on metal shelves, hung to a chain, come forward being pulled by a pair of chains, which slide within the tunnel.

The drying takes place through the forwarding of the shelves that cover the full distance of the two tunnels (one going forward and the one below for the return) and complete the drying cycle.

This type of dryer requires constant feeding, since due to the speed of the cycle, possible stops in the loading may damage the product generating waste due to breakage or deformation of the product.

The equipment to generate heat and control are the same as those of the semi-continuous dryer.

The hot air generation and the supervision system controlled by the PLC are the same as those used in the other types of dryers.

| EVOLUTION RAPID DRYER | ||||

|---|---|---|---|---|

| CODE | STOREY DIMENSION mm | TRAYS N. | OUTPUT TON/8 HOURS | DIMENSION mm |

| EVOLUTION 400 | 4000 X 800 | 52 / 64 | 80 / 120 | 5500 X 5500 |

| EVOLUTION 500 | 5000 X 950 | 52 / 64 | 120 / 150 | 6500 X 5500 |

| EVOLUTION 600 | 6000 X 950 | 52 / 64 | 150 / 200 | 7500 X 5500 |

| EVOLUTION 1000 | 6000 X 1100 | 52 / 64 | 200 / 350 | 7500 X 5500 |

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it