CUTTER

Suitable to cut perforated block at continuous output of high hourly production

Features:

Maximum hourly production ONE OR MORE OUTPUTS | 25 beats per minute | Measures at raw material: N.3 pieces at time length 212 mm N.2 pieces at time length 318 mm | Measures at fired material: N.3 pieces at time length 200 mm N.2 pieces at time length 300 mm |

| Installed power | Clutch gear-motor Cutting gear-motor Moto-variator for pushing machine | KW 0.75 KW 1.5 KW 0,75 |

|

| Machine size | Length Width Height Working level height Tape width Weight | 4.400 mm 1.300 mm 4.400 mm 1.300 mm 2.200 mm 800-900 mm 700 mm 1.280 Kg approx. |

Machine Description:

S4 cutter is completely AUTOMATIC, it needs 1 (one) only operator that does not take part in any way to machine operations, but he just follows the working process.

Automatic S4 cutter is suitable to cut only perforated block at one or more continuous outputs.

This machine has the following features:

» Manually adjustable height of the load-bearing structure;

» Linking roller between the extruder and the cutter machine;

» Broken wire indicator;

» Motorized conveyor belt for cutting synchronization;

» Carriage with rolls and cutting unit driven by gear-motor;

» Adjustable rolls to steer material;

» Spacer belt with separating rolls to permit waste drop;

» Pantograph with rolls for material advancement;

Pushing machine

» Electrical installation and operator control panel .

This machine is made by a fixed steel structure and by mobile structures, cutting units, that slide on sharpened rods and ball sleeves. Shafts and rollers are assembled over bearings and sealed ball-bearings. This machine is suitable for a continuous use: mechanical parts and gear-motors are over dimensioned compared to the required load of work. Belt has been chosen after accurate tests to grant a long-lasting performance.

Cutting Operations:

The cutting carriage, moving at the same speed of the material coming from the extruder, cuts the tile from top to bottom and vice versa. The cut can be done with or without waste. There is cut without waste when there is a single exit coming from the extruder. There is cut with waste production whene there there are two or more exits obtaining 30-40 mm of waste between the cut pieces and the pieces that have to be cut. The waste falls through a spacer device. After the cutting operations the material is moved from cutting carriage rolls to the pantograph with rolls and then to the pushing machine that groups the cut pieces and push them on the existing plant.

Cutting measures and production:

Maximum height of the material: 300 mm RAW

Maximum width of the material: 550 mm RAW

Cutting length: 212 – 265 – 318 mm RAW

Under customer request the cutting measures could be changed, but always checking the possibility to use the requested measures.

Suggested cutting wire:

Suggested cutting wire:: 0.8- 1.0 mm

Electrical installation:

Electrical installation of the cutting machine is build in respect of the current security laws. The machine is provided with electric panel fitted on the machine. The machine is supplied with a button to control the cutting station for the replacing of the cutting wires.

Optional:

S4 cutter can be supplied with the following optional features:

1. Device with disappearing roll to permit waste fall (for two or more outputs);

2. Wheels for cutter displacement;

3. Device for cutting wire advance to avoid the wire breaking

4. Half cutting system to cut at half pieces complete of:

– cutting height regulation

– possibility to choose the percentage of pieces to be cut

This machine is built in accordance with the current security laws, marked with the ce label and it is supplied with full operation manual and spare parts catalogue.

.

Suitable to cut perforated block at continuous output of high hourly production

Features:

Maximum hourly production ONE OR MORE OUTPUTS | 30 beats per minute | Measures at raw material: N.3 pieces at time length 212 mm N.3 pieces at time length 265 mm N.2 pieces at time length 318 mm | Measures at fired material: N.3 pieces at time length 200 mm N.3 pieces at time length 250 mm N.2 pieces at time length 300 mm |

| Installed power | Clutch gear-motor Cutting gear-motor | KW 0.75 KW 1.5 | |

| Machine size | Length Width Height Working level height Tape width Weight | 3.350 mm 1.200 mm 1.900 mm 750-850 mm 650 mm 810 Kg approx. |

Machine description:

S4 cutter is completely AUTOMATIC, it needs 1 (one) only operator that does not take part in any way to machine operations, but he just follows the working process.

Automatic S4 cutter is suitable to cut only perforated block at one or more continuous outputs.

This machine has the following features:

» Manually adjustable height of the load-bearing structure;

» Motorized conveyor belt for cutting synchronization;

» Carriage with rolls and cutting unit driven by gear-motor;

» Adjustable rolls to steer material;

» Spacer belt with separating rolls to permit waste drop;

» Pantograph with rolls for material advancement;

» Electrical installation and operator control panel .

This machine is made by a fixed steel structure and by mobile structures, cutting units, that slide on sharpened rods and ball sleeves. Shafts and rollers are assembled over bearings and sealed ball-bearings. This machine is suitable for a continuous use: mechanical parts and gear-motors are over dimensioned compared to the required load of work. Belt has been chosen after accurate tests to grant a long-lasting performance.

Cutting Operations:

The cutting carriage, moving at the same speed of the material coming from the extruder, cuts the tile from top to bottom and vice versa obtaining 30 mm of waste between the cut pieces and the pieces that have to be cut through a spacer device. After the cutting operations the material is moved from cutting carriage rolls to the pantograph with rolls for advancement.

Cutting measures and production:

Maximum height of the material: 300 mm raw

Maximum width of the material: 550 mm raw

Cutting length: 212 – 265 – 318 mm raw

Under customer request the cutting measures could be changed, but always checking the possibility to use the requested measures.

Suggested cutting wire:

Suggested cutting wire: 0.8- 1.0 mm

Electrical installation:

Electrical installation of the cutting machine is build in respect of the current security laws. The machine is provided with electric panel fitted on the machine. The machine is supplied with a button to control the cutting station for the replacing of the cutting wires.

Optional:

S4 cutter can be supplied with the following optional features:

1. Linking roller between the extruder and the cutter machine;

2. Device with disappearing roll to permit waste fall (for two or more outputs);

3. Broken wire indicator;

4. Wheels for cutter displacement;

5. Half cutting unit driven by gear-motor.

THIS MACHINE IS BUILT IN ACCORDANCE WITH THE CURRENT SECURITY LAWS, MARKED WITH THE CE LABEL AND IT IS SUPPLIED WITH FULL OPERATION MANUAL AND SPARE PARTS CATALOGUE.

Suitable to cut bricks at fixed or variable measures, at continuous block and high hourly production.

Features:

| Maximum hourly production | ONE OUTPUT | 8.000 pieces per hour | N.6 pieces per cut |

| Installed power | Clutch gear-motor Cutting gear-motor Block press gear-motor | KW 0.75 KW 1.85 KW 0.37 | |

| Machine size | Length Width Height Working level height Tape width Separating tape width Weight | 2.800 mm 1.200 mm 1.900 mm 750-850 mm 500 mm 400 mm 980 Kg approx. |

Machine description:

MT8 cutter is completely AUTOMATIC, it needs only 1(one) operator that does not take part in any way to machine operations, but he just follows the working process.

MT8 cutter is suitable to cut only bricks at continuous block output.

This machine has the following features:

» Manually adjustable height of the load-bearing structure;

» Motorized conveyor belt for cutting synchronization;

» Carriage with brass plates and motorized cutting unit;

» Block press driven by gear-motor;

» Spacer belt for cut pieces advancement;

» Electrical installation and operator control panel.

This machine is completely made by welded steel. The cutting carriage is composed by: a moving longitudinal carriage with brass plates for material advancement, a guillotine unit and a block press. The cutting carriage slides on sharpened rods and ball sleeves. Shafts and rollers are assembled over bearings and sealed ball-bearings. This machine is suitable for a continuous use: mechanical parts and gear-motors are over dimensioned compared to the required load of work. Tape has been chosen after accurate tests to grant a long-lasting performance.

Cutting operations:

The cutting carriage, moving at the same speed of the material coming from the extruder, cuts the tile from top to bottom and vice versa. Using the block press the material adheres to the inferior plates, in order to avoid that the cutting wire moves and raise the block.

After these operations the material moves from the plates to a spacer belt for material advancement.

Cutting measures:

Maximum height of the material: 150 mm raw

Maximum width of the material: 300 mm raw

Minimum cutting length: 63 mm raw

Under customer request the cutting measures could be changed, but always checking the possibility to use the requested measures

Suggested cutting wire:

Suggested cutting wire: 0.8- 1.0 mm

Electrical installation:

Electrical installation of the cutting machine is build in respect of the current security laws. The machine is provided with electric panel fitted on the machine. The machine is supplied with a button to control the cutting unit for the replacing of the cutting wires.

Optional:

MT8 cutter with block press can be supplied with the following optional features:

1. Linking roller between the extruder and the cutter machine;

2. Wetting roll with tank for anti-adherence liquid;

3. Wheels for cutter displacement .

THIS MACHINE IS BUILT IN ACCORDANCE WITH THE CURRENT SECURITY LAWS, MARKED WITH THE CE LABEL AND IT IS SUPPLIED WITH FULL OPERATION MANUAL AND SPARE PARTS CATALOGUE.

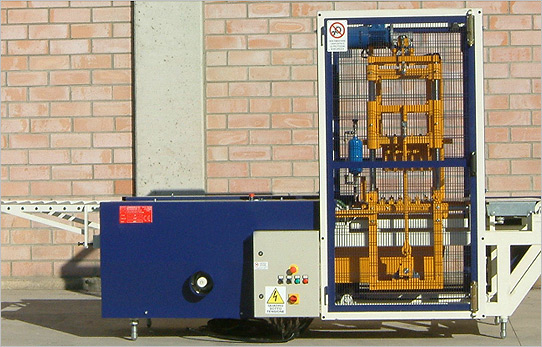

CUTTING SYSTEM COPOSED BY:

A) ELECTRONIC CUTTER MACHINE

B) AUTOMATIC MULTIPLE CUTTING DESK WITH TWO CUTTING UNITS

A) ELECTRONIC CUTTER MACHINE

Suitable to cut perforated or full block at fixed or changeable measure, at one or more outputs, with high hourly production.

Features:

| Max hourly production | 15 beats per minute | ||

| Installed power | N°1 Brushless gear-motor for cutting carriage advancement N°1 Gear-motor for vertical cut N°2 Gear-motors to push the block | Nm 6 KW 1,5 KW 1,1 | |

| Dimensioni macchina | Lunghezza (Varia secondo il filone Length (It depends on the block to cut) Width Height Working level height Belt width Weight | 2.650 mm 1.400 mm 2100 mm 800-900 mm adjustable 600-900 mm 1.350 Kg approx. | 4000 mm 1.800 mm 2.100 mm 800-900 mm adjustable 900-1200 mm 1.700 Kg approx. |

Machine description:

The cutter machine is completely AUTOMATIC, it needs only 1 (one) operator that does not take part in any way to machine operations, but he just follows the working process. The cutter machine is suitable to cut only perforated or full block at one or more continuous outputs.

This machine has the following features:

1. Manually adjustable height of the load-bearing structure;

2. Rubberized roll with encoder to check material speed;

3. Cutting carriage with rolls, with advancing driven by reduction gear with brushless engine,

4. Encoder to gather the cutting length of the piece;

5. Mobile cutting unit driven by gear-motor, to cut block at fixed or variable measures;

6. Conveyor tapes for pushing and throwing pieces;

7. Electrical installation and push-bottom panel – ( if it is supplied to the customer only the cutter machine)

This machine is made by a fixed steel structure and by a mobile structure, the cutting unit, that slides on sharpened rods and ball sleeves. Shafts and rollers are assembled over bearings and sealed ball-bearings. This machine is suitable for a continuous use: mechanical parts and gear-motors are over-dimensioned compared to the required load of work. Belt has been chosen after accurate tests to grant a long-lasting performance.

Cutting operations:

The speed of the material is detected by an encoder fitted on the rubberized roll. The cutting carriage, moving at the same speed of the material, cuts it from top to bottom and vice versa. Cut material is then sent from the pushing belts to the cutting desk.

Cutting measures:

Height of the material: from 50 mm 350 mm raw

Width of the material: from 200 mm 70 mm raw – from 700 mm 1100 mm raw

Cutting Length: from 1000 3000 mm raw

Under customer request the cutting measures could be changed, but always checking the possibility to use the requested measures.

Suggested cutting wire:

Suggested cutting wire: 0,8 – 1 mm

Electrical installation:

Electrical installation of the cutting machine is build in respect of the current security laws. The machine is provided with connectors for the control board. The electric control board has the electric and electronic devices and the control board to control all the functions of the machine.

The control panel is supplied with an operative keyboard to set cutting measures and to modify other parameters, if necessary.

Optional:

Automatic cutter machine can be supplied with the following optional features:

1. Pneumatic device to stretch the wire;

2. Linking roller between the extruder and the cutter

3. Broken wire indicator;

4. Wheels for cutter displacement.

THIS MACHINE IS BUILT IN ACCORDANCE WITH THE CURRENT SECURITY LAWS, MARKED WITH THE CE LABEL AND IT IS SUPPLIED WITH FULL OPERATION MANUAL AND SPARE PARTS CATALOGUE.

————————————————————————————————————————————————————————————

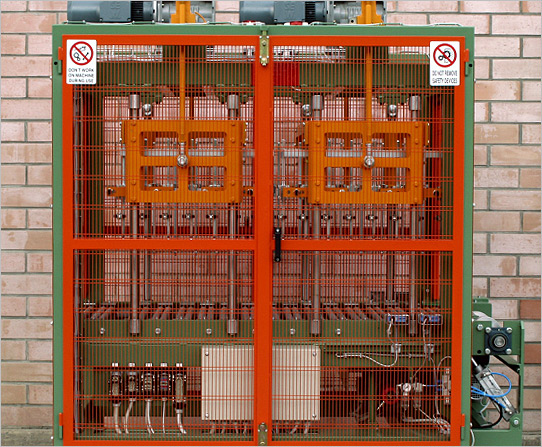

B) AUTOMATIC MULTIPLE CUTTING DESK WITH TWO CUTTING UNITS

Suitable to cut perforated or full blocks with one or more continuous outputs, with fixed or variable measure, at high hourly production.

Features:

Max hourly production | 10 beats per minute | ||

| Installed power | Gear motor driven by inverter to control cutting desk rolls N.2 Cutting gear motors | KW 2,2 KW 2,2 | |

| Machine size | Length Width Height Working level height Belt width Weight | 2.400 mm 1.600 mm 2.165 mm 800-900 mm customizable From 200 mm to 700 mm 2.000 Kg approx. | 3.000 mm 2.000 mm 2.165 mm 800-900 mm customizable From 700 mm to 1.100 mm 2.500 Kg approx. |

Machine description:

The multiple cutting desk is completely automatic, it needs only 1 (one) operator that does not take part in any way to machine operations, but he just follows the working process. Multiple cutting desk is suitable to cut one or more perforated blocks with fixed or variable measure.

This machine has the following features:

» Manually adjustable height of the load-bearing structure;

» N.2 mobile cutting units for cutting more pieces at the same time;

» Waste produced at the beginning and at the end of the long segment coming from the block cutting machine;

» Conveyor with motorized rolls driven by reduction gear with retroactionated engine;

» Pneumatic device for waste unloading;

» Electrical installation and push bottom panel .

This machine is made by a fixed steel structure and by mobile structures: cutting units that slide on sharpened rods and ball sleeves. Shafts and rollers are assembled over bearings and sealed ball-bearings. This machine is suitable for a continuous use: mechanical parts, cutting and rollers gear motors are over dimensioned compared to the required load of work.

Belt has been chosen after accurate tests to grant a long-lasting performance.

Cutting operations:

The segment coming from the thread cutter is positioned on the multiple cutting bench and stops in the position suitable for cutting by means of a photocell. At the same time the two vertical arches cut the pieces to the pre-established size with trimming at the ends of the segment. The cut is made from top to bottom with a harmonic thread (or braid). The arches return to the upper position to “empty”: first the archway that is located towards the entrance of the lodging rises and then, when all the cut pieces have come out, the second bow rises too: this operation allows to anticipate the entry of the next segment to be cut. The formed trimming falls by means of a pneumatic device with a retracted roller and subsequently the material advances through the rollers of the bench.

Cutting measures:

Height of the material: from 50 a 350 mm raw

Width of the material: from 200 a 700 mm raw Or from 700 a 1100 mm raw

Cutting lenght: from 200 a 500 mm raw

Under customer request the cutting measures could be changed, but always checking the possibility to use the requested measures.

Suggested cutting wire:

Suggested cutting wire: 0,8 – 1 mm

Electrical installation:

Electrical installation of the cutting machine is build in respect of the current security laws. The machine is provided with connectors for the control board. The electric control panel has the electric and electronic devices and the buttons to control all the functions of the machine.

The control panel is supplied with an operative push-bottom panel to modify other parameters, if necessary.

Optional features:

Multiple cutting desk can be supplied with the following optional features:

» Waste gathering belt;

» Pneumatic device for wire stretching ;

» Broken wire indicator;

» Wheels for cutter displacement.

THIS MACHINE IS BUILT IN ACCORDANCE WITH THE CURRENT SECURITY LAWS, MARKED WITH CE LABEL AND IT IS SUPPLIED WITH FULL OPERATION MANUAL AND SPARE PARTS CATALOGUE.

PROject genetar: 60Ton

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it